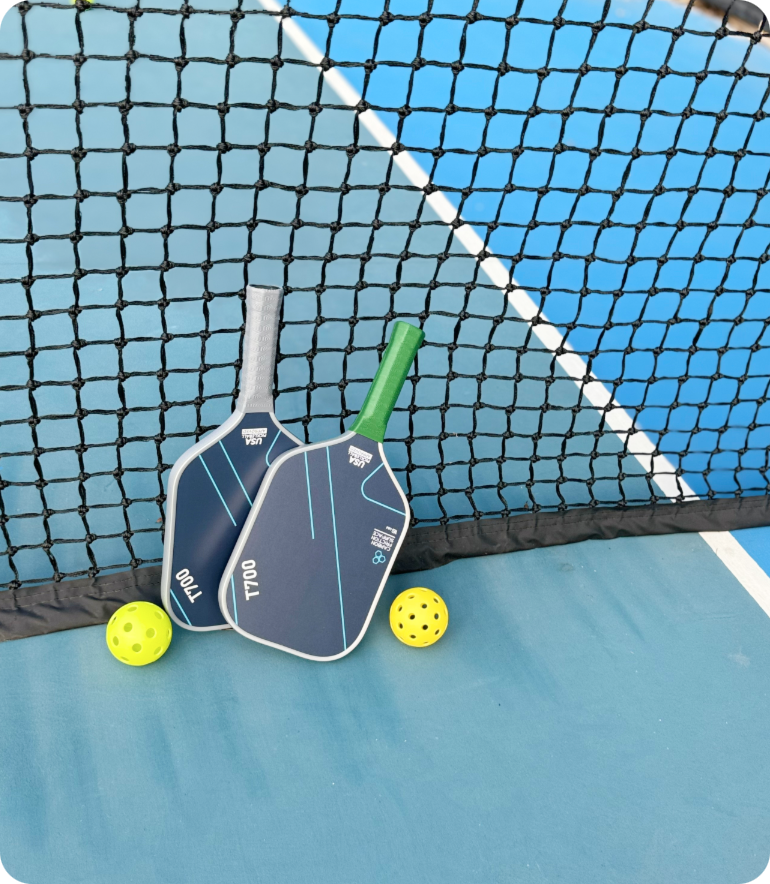

Conduct in-depth research on the comfort, anti-slip and durability requirements of pickleball players

for the grip, define the direction of differentiated design, and optimize the product development

process to precisely match the pain points of users.

During the grip design stage, we simultaneously considered the production process and the actual

needs of the players, optimizing details such as the anti-slip texture and the fit of the shock-absorbing

layer to ensure the rapid delivery of an innovative product that combines both hand feel and reliability.

• Specification: Diameter (min. &max.), Length & Thickness

• Texture:From the texture to the arc, it is 100% in line with your grip habits - making every swing feel

like an extended arm

•Pattern:Highlight your personal style and make the grip the visual focus of your racket

•Color:Your lucky color + your exclusive grip = Invincible mental edge

• From idea to designing, drawing

We transform your requirements into a realistic touch, strictly matching the diameter, texture,

hardness and shock absorption requirements you specify. Ensure every detail before mass production.

Conduct in-depth research on the comfort, anti-slip and durability requirements of pickleball players

for the grip, define the direction of differentiated design, and optimize the product development

process to precisely match the pain points of users.

During the grip design stage, we simultaneously considered the production process and the actual

needs of the players, optimizing details such as the anti-slip texture and the fit of the shock-absorbing

layer to ensure the rapid delivery of an innovative product that combines both hand feel and reliability.

• Specification: Diameter (min. &max.), Length & Thickness

• Texture:From the texture to the arc, it is 100% in line with your grip habits - making every swing feel

like an extended arm

•Pattern:Highlight your personal style and make the grip the visual focus of your racket

•Color:Your lucky color + your exclusive grip = Invincible mental edge

• From idea to designing, drawing

We transform your requirements into a realistic touch, strictly matching the diameter, texture,

hardness and shock absorption requirements you specify. Ensure every detail before mass production.

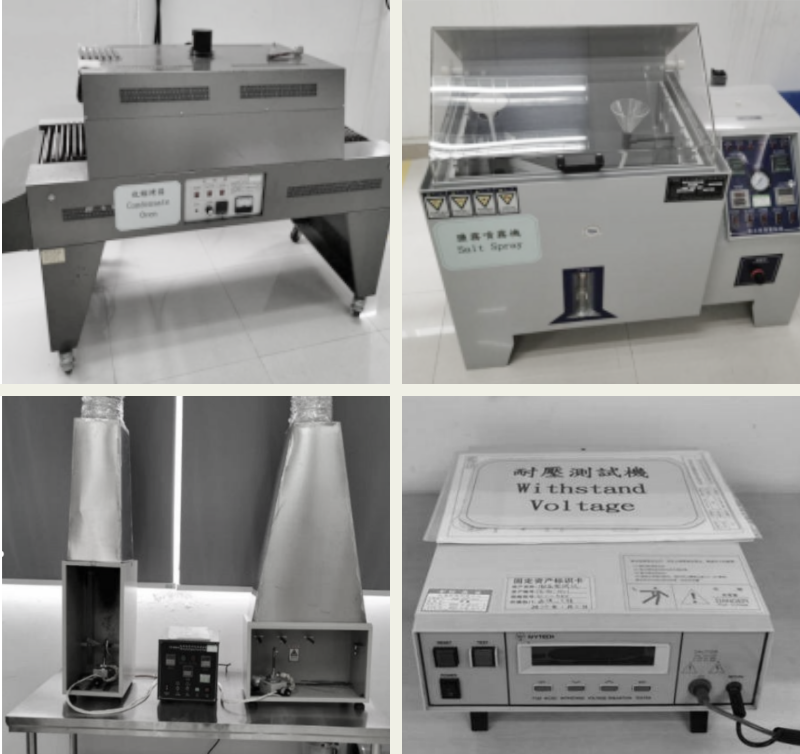

Before the mass production starts, we ensure that the key indicators such as the anti-slip performance and the

durability of the shock-absorbing layer of the grip meet the standards through high-frequency fatigue tests,

environmental temperature and humidity simulations, and actual impact verification. Meanwhile, we rehearsed

the production rhythm and quality inspection nodes to ensure that both performance and efficiency met the

standards when the orders were delivered.

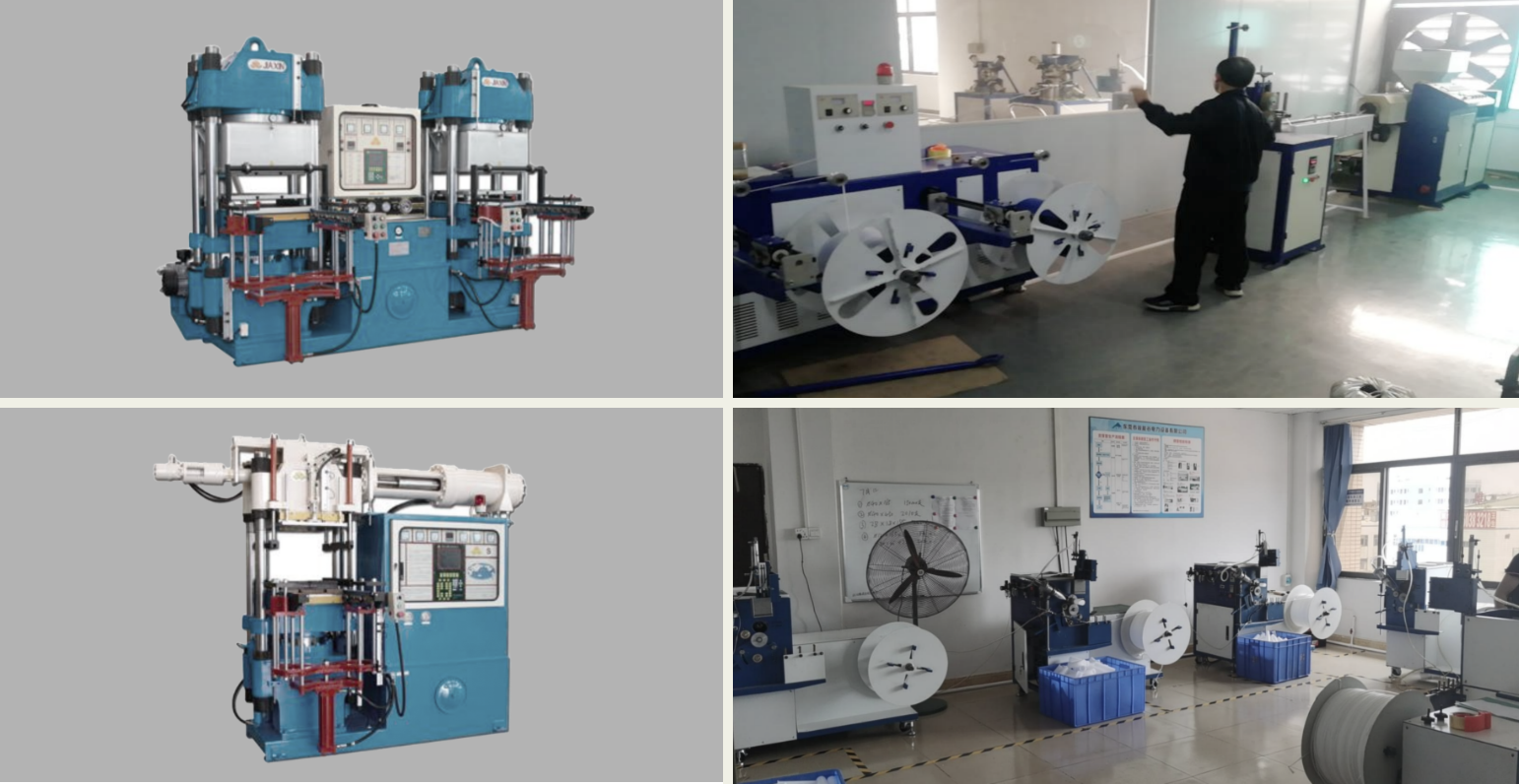

In the production of Peak racket grips, we adopt an efficient model where automated machines and exquisite

craftsmanship work together to ensure that each grip meets the quality standards of precision, durability and

comfort.

1

2

3

12 years of experience in sports product accessories

design,manufacturing, and supply chain management.

12 core team members, average 15 years industry experience.

Q&A